Elevate your business with expert sourcing solutions

Our mission is to ensure high quality products at most competitive price.

HR Coil

Hot Rolled Coil (HRC) refers to a type of steel coil that is produced by rolling semi-finished steel slabs or billets through a series of rollers above its recrystallization temperature. This process results in a product with a rough surface finish and relatively loose tolerances on its dimensions. Hot rolled coils are commonly used in various industries, including construction, automotive, and manufacturing, for applications such as structural components, pipes, and automotive frames. Due to its relatively lower cost and efficient production process, hot rolled coil is widely utilized in the steel industry.

CR Coil

Cold Rolled Coils are steel coils that have undergone a cold rolling process, where the steel is rolled at room temperature or slightly below it. This process produces steel with tighter dimensional tolerances and improved surface finish compared to hot rolled coils. Cold rolled coils are often used in applications where precise dimensions, smooth surface finish, and excellent mechanical properties are required, such as in automotive manufacturing, appliances, construction, and electronics. Cold Rolled Coils have better, more finished surfaces with closer tolerances, Bars are true and square, and often have well-defined edges and corners and Tubes have better concentric uniformity and straightness Cold rolled steel is ideal for products demanding exact dimensions and improved surface characteristics.

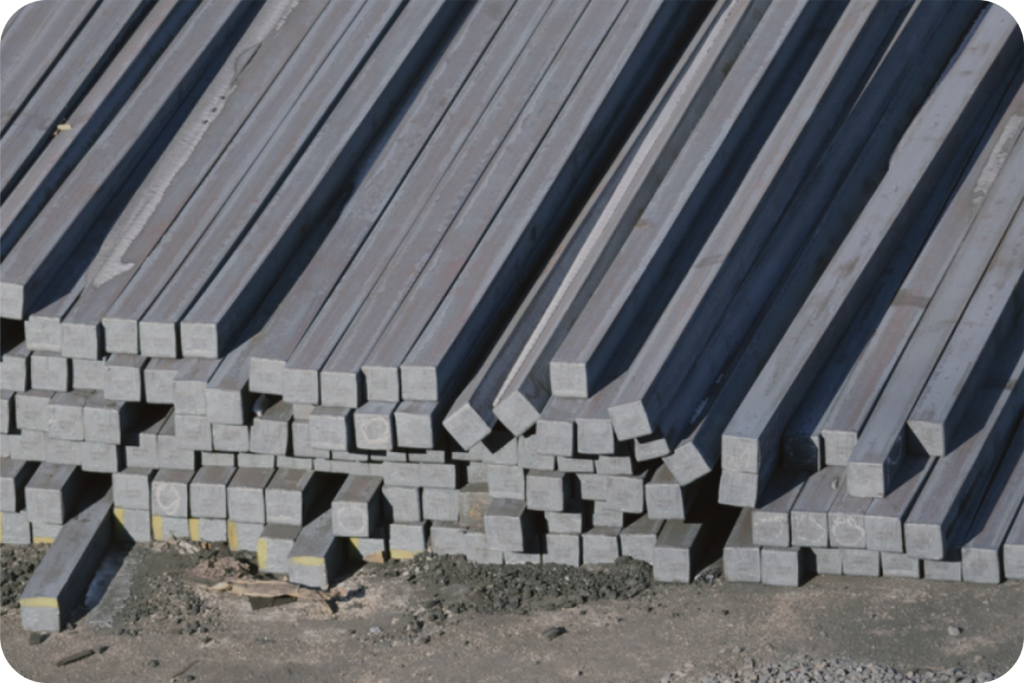

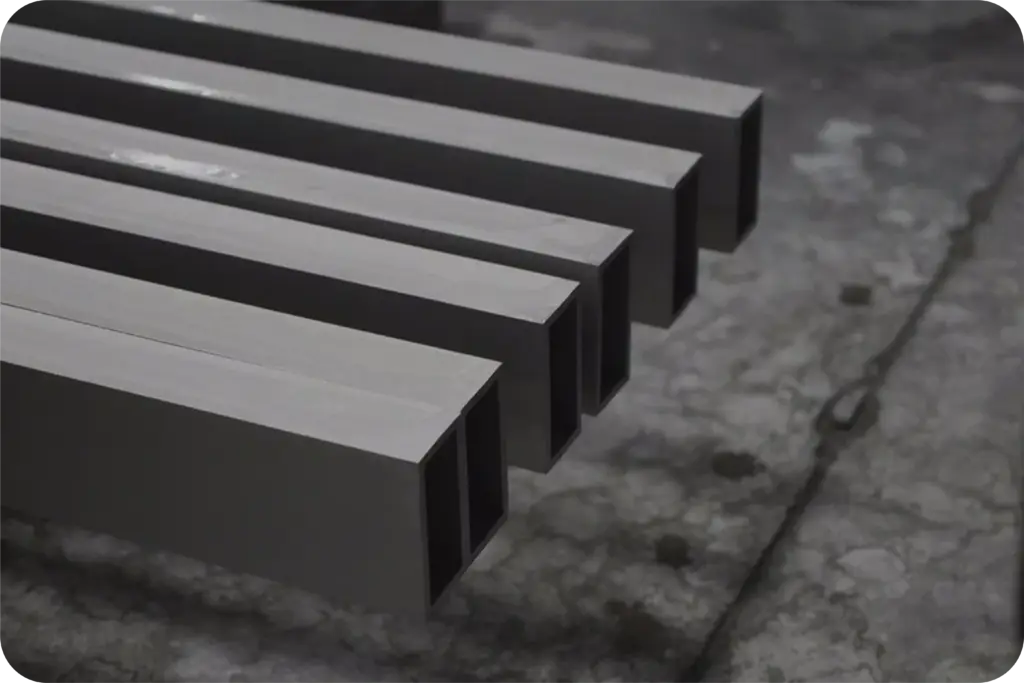

Billets

Steel billets are semi-finished rectangular or square-shaped metal products, typically produced through the process of casting molten steel into molds. They serve as the starting material for manufacturing a wide variety of steel products such as rods, bars, plates, and structural shapes. Billets are generally made from carbon steel and its size and quality can vary depending on the intended application. After production, steel billets are further processed through rolling, forging, or extrusion to create final products used in construction, automotive, machinery, and other industries. The quality of the billet is crucial, as it affects the final product's strength, durability, and performance.

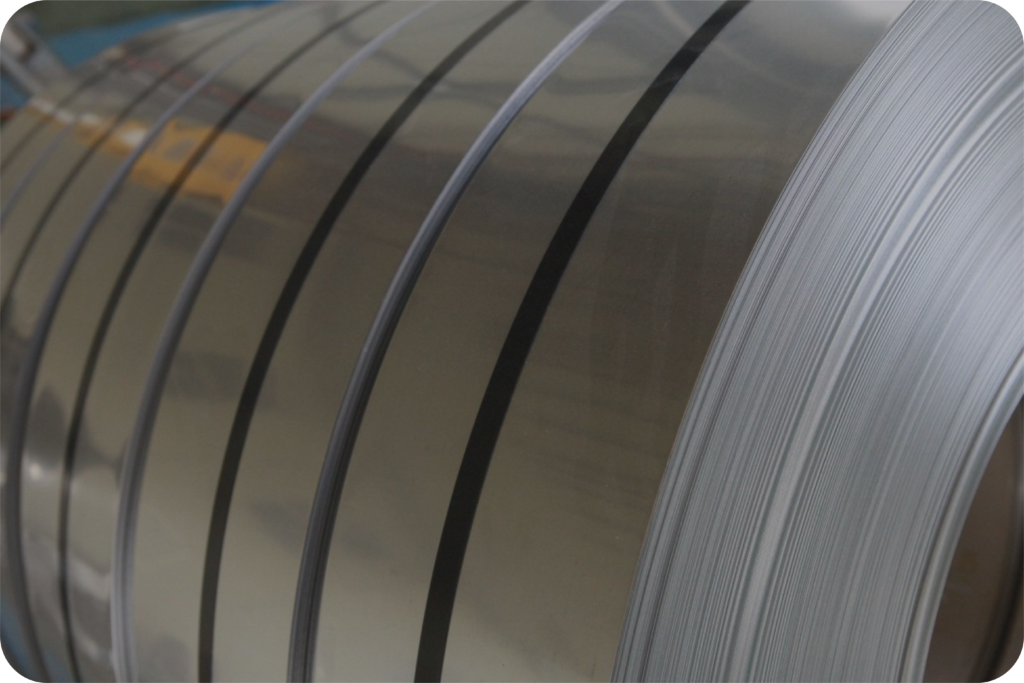

Carbon Steel Strip

Carbon Steel Strips are narrow, flat-rolled steel products made primarily from carbon steel, an alloy of iron and carbon. These strips are produced through a process called strip rolling, where steel coils are passed through a series of rollers to achieve the desired thickness and width. Carbon steel strips come in various grades and thicknesses, depending on the intended application. They are often classified based on their carbon content and additional alloying elements. Some common grades of carbon steel strips include low carbon steel (mild steel), medium carbon steel, and high carbon steel. Carbon steel strips offer several advantages, including high strength, durability, ease of fabrication, and relatively low cost compared to other materials. Their versatility and wide range of applications make them essential in various industrial sectors.

Carbon Steel Wire

Carbon Steel Wire refers to a type of wire made primarily from carbon steel, which is an alloy of iron and carbon. Carbon steel wires are widely used in various applications due to their strength, durability, and versatility. They are commonly used in manufacturing processes such as wire drawing, cold heading, and wire forming. Carbon steel wires come in various grades and configurations, depending on the intended application. They can be plain carbon steel wires or alloyed with other elements such as manganese, silicon, or chromium to enhance specific properties like strength, corrosion resistance, or machinability.

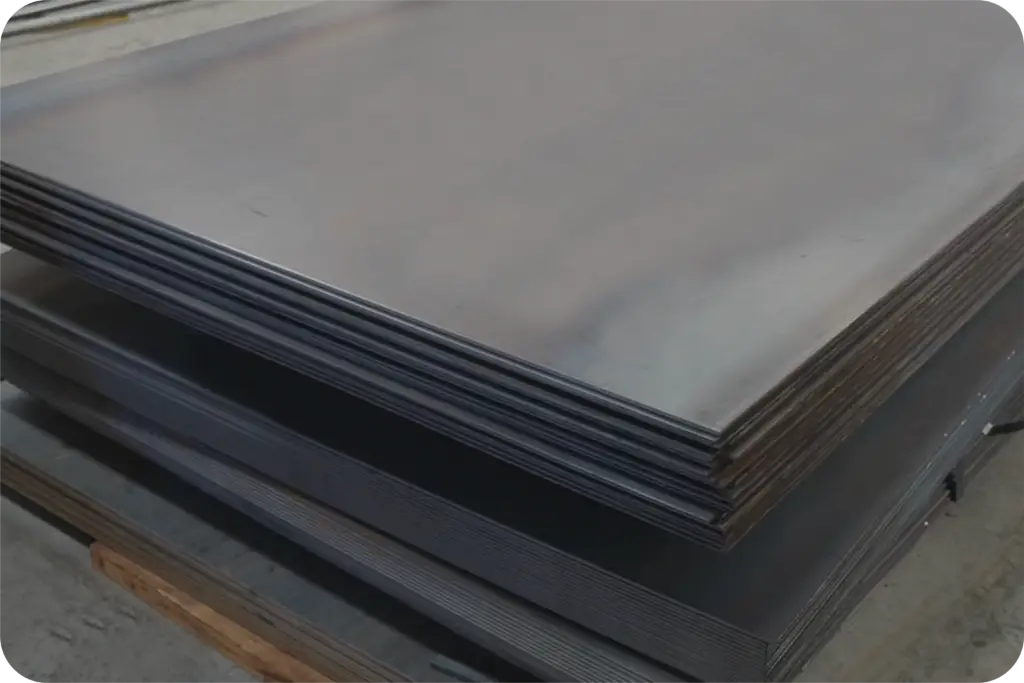

Carbon Steel Plates

Carbon Steel Plates are flat-rolled steel products primarily composed of carbon and iron, with trace amounts of other elements. They are produced through a process of hot rolling or cold rolling, followed by heat treatment and/or surface finishing to achieve the desired properties and dimensions. Carbon steel plates come in various grades and thicknesses, depending on the specific requirements of the application. They are often classified based on their carbon content and additional alloying elements. Some common grades of carbon steel plates include Low Carbon Steel (Mild Steel), Medium Carbon Steel, High Carbon Steel.

Carbon Steel Hex Bar

Carbon Steel Hex Bars are solid bars of carbon steel with a hexagonal cross-section. They are commonly used in various industrial applications where strength, durability, and machinability are required. The hexagonal shape of these bars provides greater surface contact when compared to round bars, making them useful for applications where secure fastening or precise alignment is necessary.

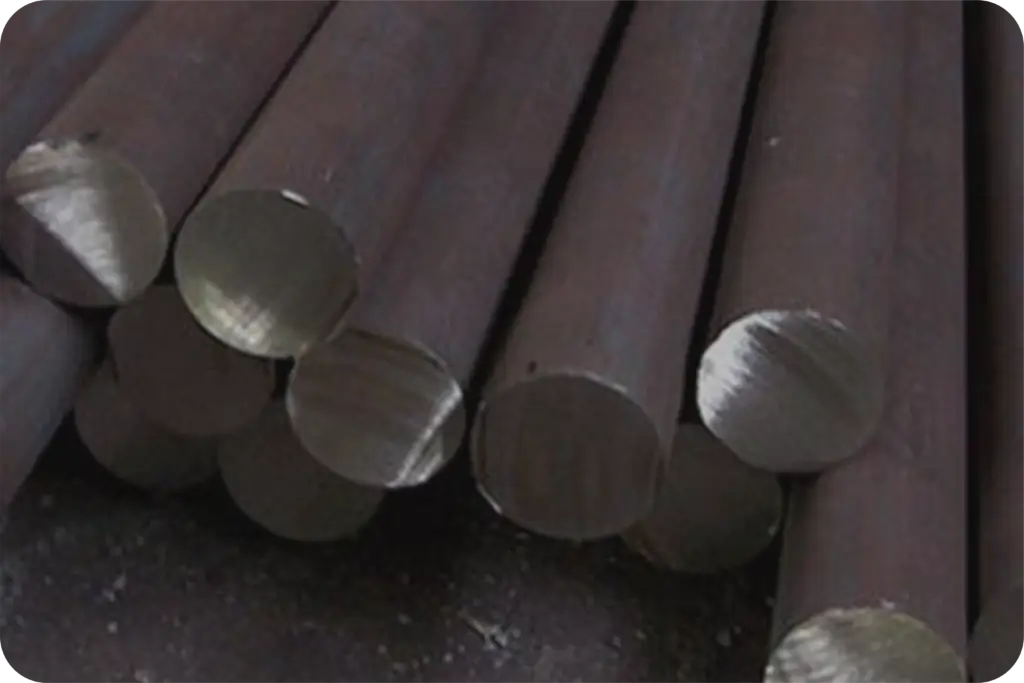

Carbon Steel Rods

Carbon Steel Rods, also known simply as steel rods, are solid cylindrical bars made primarily of carbon and iron, with small amounts of other elements. They are commonly used in a wide range of industrial applications due to their strength, durability, and versatility. When selecting carbon steel rods for a particular application, it's essential to consider factors such as the required mechanical properties, surface finish, dimensional accuracy, and any additional treatments needed to meet performance specifications and environmental conditions.

Carbon Steel Profile

Carbon Steel Profiles encompass a wide range of structural shapes and sections made from carbon steel, which is an alloy primarily composed of iron and carbon. These profiles are used across various industries for structural and architectural purposes. Some common types of carbon steel profiles include Beams, Channels, Angles, Tubing and pipes, Rails, Plates & Sheets and Expanded Metals and Grating.

Carbon Steel Round Tube

Carbon Steel Round Tubes come in various diameters, wall thicknesses, and lengths to suit different applications. Common diameters range from fractions of an inch to several inches, while wall thicknesses can vary based on the required strength and structural integrity. Lengths are typically available in standard sizes or can be cut to custom lengths. Carbon steel round tubes find applications in industries such as construction, manufacturing, automotive, machinery, and infrastructure. They are commonly used for structural support, framework, mechanical components, fluid transportation (such as water, oil, and gas), and heat exchangers.

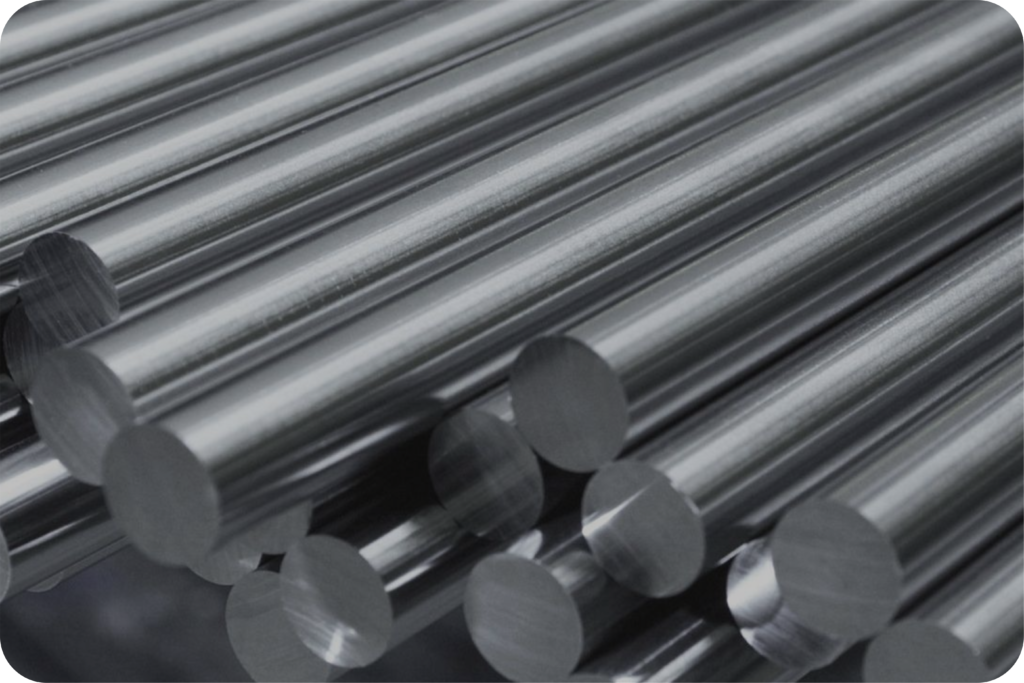

Carbon Steel Round Bar

Carbon Steel Round Bars are solid cylindrical bars made primarily of carbon and iron. These bars are widely used in various industries due to their strength, versatility, and affordability. Carbon steel round bars are typically manufactured through processes such as hot rolling, cold drawing, or machining. Hot rolling involves heating the steel billet to high temperatures and then passing it through rollers to achieve the desired diameter. Cold drawing involves pulling the steel through a series of dies at room temperature to achieve precise dimensions and surface finish.

Ductile Iron Pipe

Ductile iron pipe (DI pipe) is a type of cast iron pipe known for its high strength, durability, and ductility. It is widely used in various municipal and industrial applications for transporting water, sewage, and other fluids. Ductile iron pipe is made from ductile cast iron, which is an alloy of iron, carbon, and silicon. It also contains small amounts of other elements such as manganese, magnesium, and sulphur. These alloying elements give ductile iron its unique properties, including high strength and ductility. Ductile iron pipe is available in various sizes and pressure ratings to suit different applications. It typically comes in lengths of 18 to 20 feet and diameters ranging from a few inches to several feet. Ductile iron pipe is typically installed using mechanical joints, flanged connections, or push-on joints.

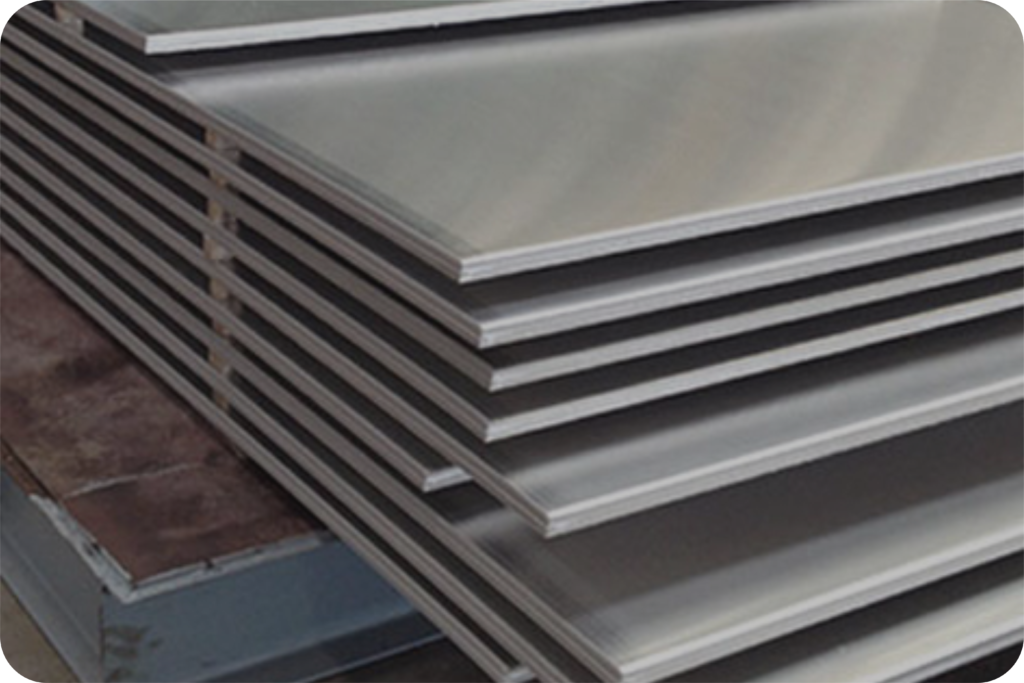

Carbon Steel Sheets

Carbon Steel Sheets are flat-rolled steel product and can have different surface finishes depending on the manufacturing process and intended application. Common surface finishes include hot-rolled, cold-rolled, and coated finishes. Hot-rolled sheets typically have a rough surface texture, while cold-rolled sheets have a smoother surface finish. Coated sheets may have additional surface treatments such as galvanizing or painting to enhance corrosion resistance or aesthetics.

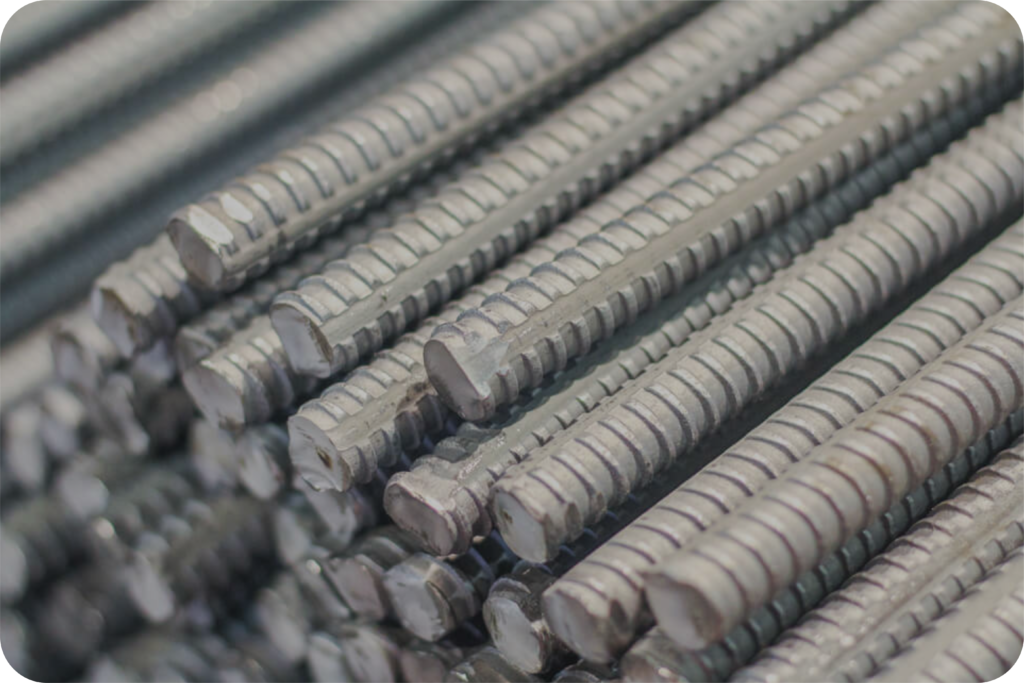

Re Bars

Rebars (short for reinforcing bars) are steel rods or bars used to reinforce concrete structures, providing tensile strength and improving the material's ability to withstand pulling forces. Concrete is strong in compression but weak in tension, so rebars are embedded within it to prevent cracking and failure under stress. They are typically made of carbon steel, though some may be coated to resist corrosion. Rebars have a textured surface, which allows them to bond securely with concrete. They come in various diameters, lengths, and grades, and are essential in the construction of buildings, bridges, highways, and other infrastructure to ensure structural integrity and longevity.